Sulfide solid state electrolytes are extremely environment sensitive and prone to oxidation,hydrolysis-induced degradation during grinding process, posing significant challenges to R&D and production.

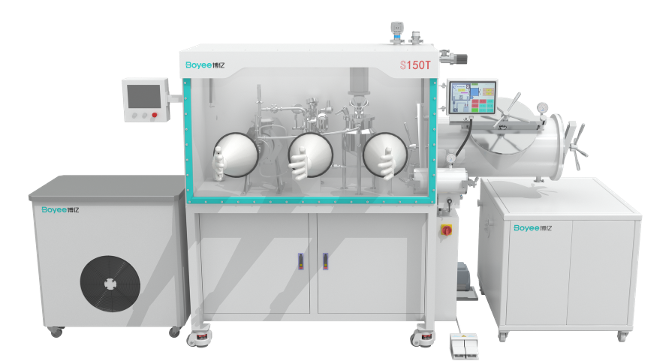

Boyee Glovebox Sealed Integrated Bead Mill delivers a complete process solution specifically designed for such sensitive materials.

01

Moisture and Oxygen Sensitive Material is Prone to Oxidation and Hydrolysis.

Sulfide solid-state electrolytes exhibit extreme sensitivity to moisture and oxygen.When developed or produced in conventional environment, these materials are highly susceptible to oxidation and hydrolysis, resulting in significant degradation of their electrochemical performance.

Image: Boyee Glovebox Sealed Integrated Bead Mill

Boyee equipment creates an ultra low moisture and oxygen environment through repeatedly inert gas purging and multi-stage displacement, completely isolating air and moisture throughout the entire process from material feeding to discharge, effectively preserving material activity.

02

Non-uniform Grinding Affects Formulation Verification

During small-scale R&D trial stage, nanoscale particles are tend to agglomerate, and are difficult to achieve uniform grinding particle size, which significantly compromising formulation verification efficiency.

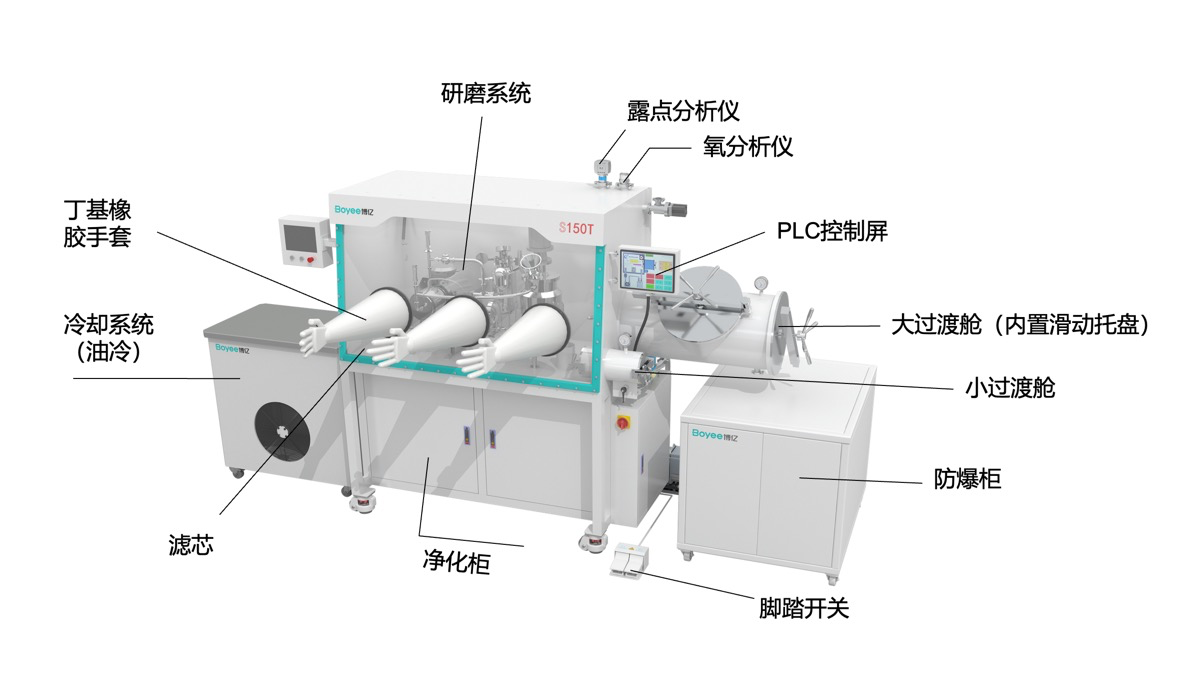

Boyee Glovebox Sealed Integrated Bead Mill, equipped with PLC precise speed control system, features zirconia ceramic rotor grinding system (wear-resistant ceramic grinding components), achieving nanoscale uniform grinding and dispersing agglomerated particles.

Image:Schematic Diagram of the Overall Structure of Boyee Glovebox Sealed Integrated Bead Mill

Meanwhile, the transition chamber design enables safe material transfer in and out, allowing operations such as pre-mixing and sampling completed inside the chamber, reducing the risk of contamination.

03

High Transition Costs from Lab-Scale Trials to Mass Production

The lab-scale trial data is difficult to be reused,and the long iteration cycles and high costs of mass production processes hinder the advancement of industrialization.

Boyee equipment features parameter storage and traceability functions, allowing lab-scale parameters to be directly applied to pilot and mass production stages. From lab-scale testing to post-processing, the system provides fully enclosed protection, precise grinding, and closed-loop process advantages, offering reliable support for research institutions and enterprises to accelerate the R&D and mass production process of solid-state electrolytes.