The global new energy industry is undergoing a technological leap from liquid batteries to solid-state batteries. As the core materials of all-solid-state batteries, the large-scale preparation technology of oxide and sulfide solid electrolytes has become a key focus of the industry's efforts.

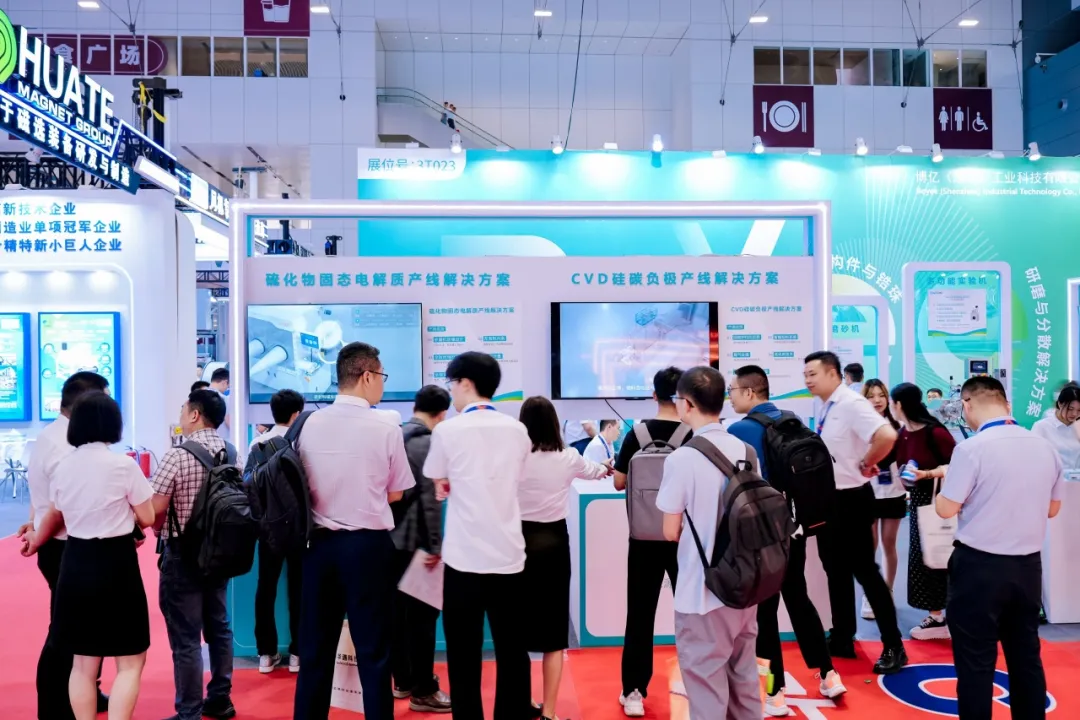

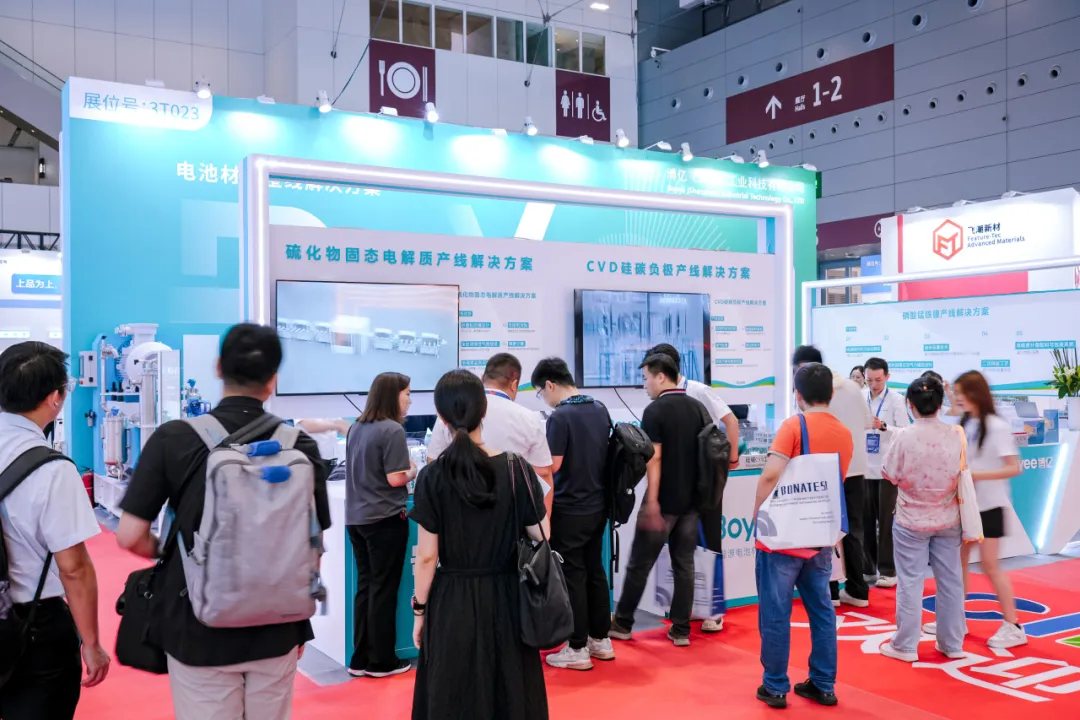

Boyee (Shenzhen) Industrial Technology Co., Ltd. showcased its full-process production line solutions at CIBF2025, directly addressing the pain points of industrialization and driving breakthroughs in material performance through equipment innovation.

1. Exhibition Highlights: Preparation and Industrialization of Solid Electrolytes

As the core material of the next-generation lithium batteries, the large-scale preparation of solid electrolytes still faces three major challenges: material stability, process controllability and cost-effectiveness.

Based on years of experience in the preparation technology of nanomaterials, the Boyee team has proposed innovative solutions to the technical bottlenecks of oxide and sulfide systems.

2. Oxide Solid Electrolyte Production Line Solutions

Oxide solid electrolytes have great potential in improving battery performance, yet their preparation process is fraught with difficulties.

The material is prone to moisture, which affects its stability. Poor uniformity of mixing leads to uneven performance. Sticking to the saggars during sintering increases costs and affects quality. Problems such as large crushing and wear in jet milling, defects in premixing and dispersion performance, as well as difficult depolymerization, poor dispersion and uneven distribution in the grinding section have long plagued the scientific research and industrial sectors.

With its profound technological accumulation and innovation capabilities, Boyee has developed a series of advanced technologies and solutions to address these pain points, facilitating the optimization of the preparation process and the advancement of industrialization of oxide solid electrolytes.

3. Solution for Sulfide Solid Electrolyte Production Line

Sulfide solid electrolytes have become a research hotspot due to their unique performance advantages. However, the materials are extremely sensitive to moisture and oxygen, production requires strict environmental conditions, and there are challenges such as waste gas treatment issues, equipment being prone to corrosion, and prominent particle agglomeration problems.

Boyee has deeply analyzed these challenges, applied cutting-edge technologies, and made significant progress in material modification, process innovation, equipment protection, etc., providing practical solutions for the large-scale production of sulfide solid electrolytes.

We sincerely invite you to visit Hall 3-3T023. At this exhibition, Boyee has carefully prepared a rich array of display contents, covering solid electrolyte-related technologies, CVD silicon-carbon anodes, battery material production lines and other solutions.