As solid-state batteries gain momentum for their potential advantages in safety and energy density, oxide solid-state electrolytes are widely regarded as one of the most promising routes toward industrialization, thanks to their high stability and material compatibility. However, scaling up their production remains a major challenge for the industry.

Key Manufacturing Challenges

In practical manufacturing, oxide solid-state electrolytes face several persistent process-related issues, including:

● High moisture sensitivity of raw materials

● Difficulty in achieving uniform multi-component mixing

● Limited stability during sintering

● Poor control over particle size distribution

These challenges have slowed the transition from laboratory research to continuous and scalable production, making material consistency a critical concern for the solid-state battery value chain.

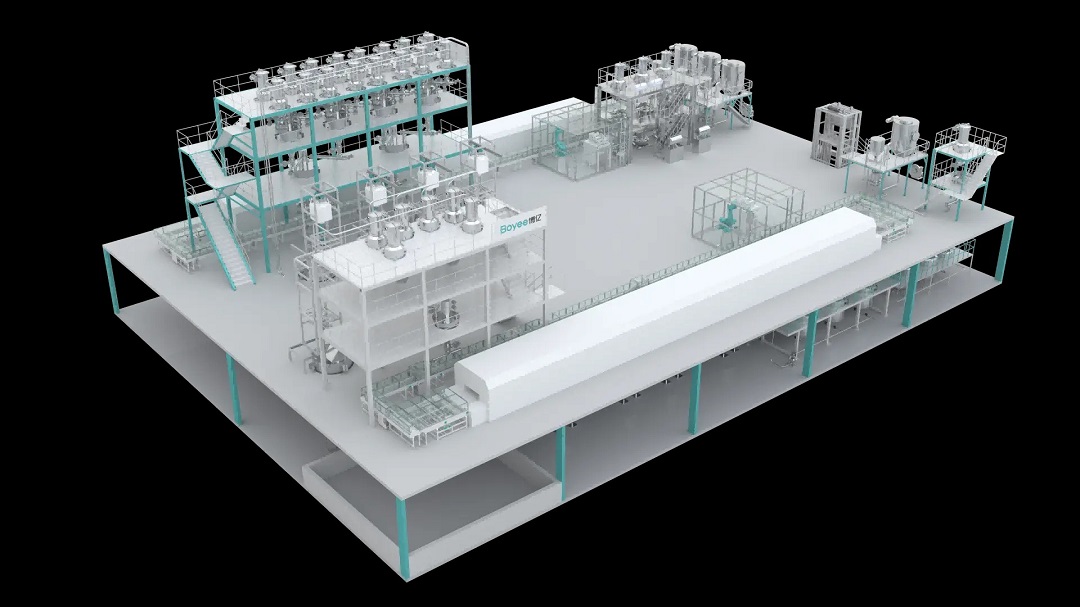

Integrated Production Line Solution

In response, Boyee has introduced its Oxide Solid-State Electrolyte Production LineSolution, drawing on its long-standing experience in powder engineering and material processing equipment. The solution adopts a system-level approach to oxide electrolyte manufacturing, integrating and optimizing key process stages such as:

● Raw material handling

● Mixing and dispersion

● Grinding and sintering

● Enclosed conveying and packaging

The overall design emphasizes process enclosure, continuity, and controllability to support stable and repeatable production.

Process-Oriented Equipment Integration

At the critical stage of fine grinding and particle size control, the production line incorporates a well-matched Bead Grinding Machine. By aligning grinding performance with upstream and downstream processes, the solution:

● Improves particle size distribution consistency

● Reduces batch-to-batch variability

● Provides a stable foundation for subsequent processing steps

Rather than focusing on standalone equipment, the approach prioritizes coordinated process integration.

Supporting Industrial Scale-Up

From a system design perspective, the solution also highlights:

● Enclosed material transfer to minimize external contamination

● Modular layouts to enhance process connectivity

● Improved repeatability and operational reliability

These features provide a practical reference for scaling oxide solid-state electrolyte production from pilot lines to industrial manufacturing.

Industry Outlook

Industry analysts note that as solid-state battery development moves into engineering validation and industrial deployment, upstream material preparation capabilities will play an increasingly decisive role. Integrated process design and coordinated equipment deployment are expected to be key enablers of commercialization.

Boyee stated that it will continue to focus on process integration and equipment innovation in the new energy materials sector, supporting further improvements in consistency, stability, and large-scale manufacturing capability for solid-state battery materials.