With the rapid development of new energy technologies, solid electrolyte, as a key component of next-generation battery technology, is receiving more and more attention.

Oxide solid electrolyte and sulfide solid electrolyte, as the two main technical routes, show different advantages in material properties, preparation technology and application prospects.

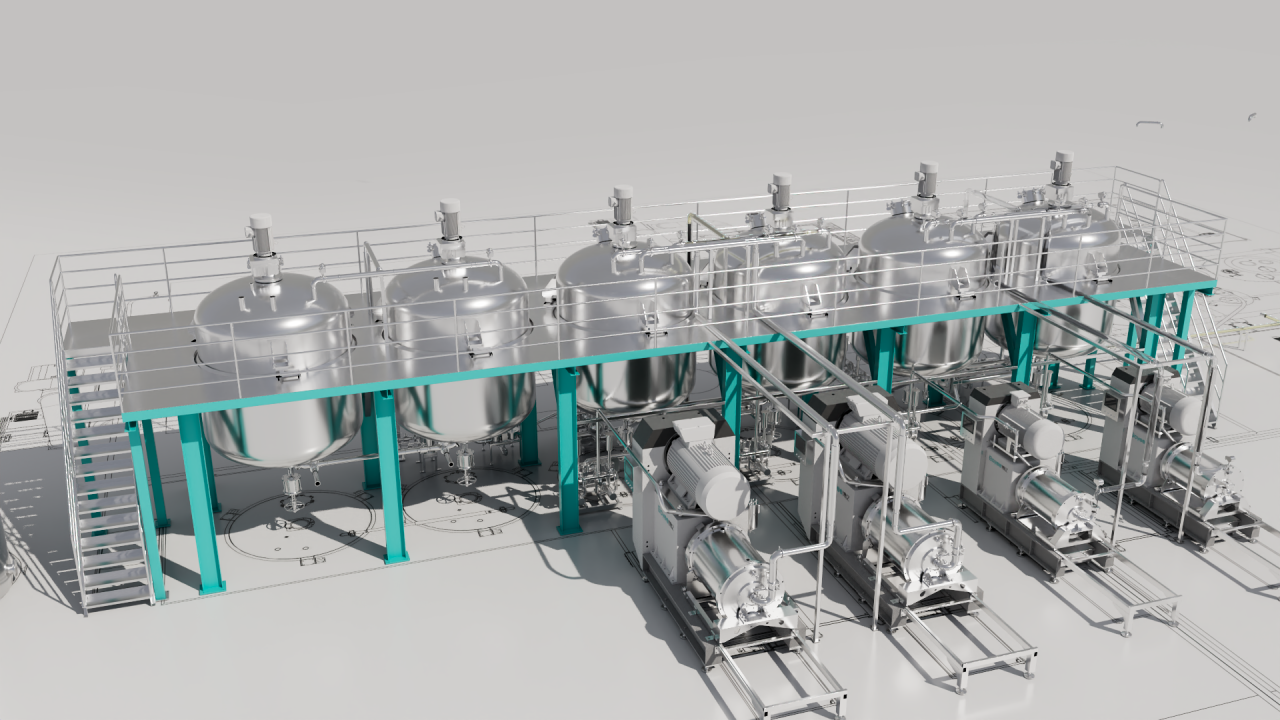

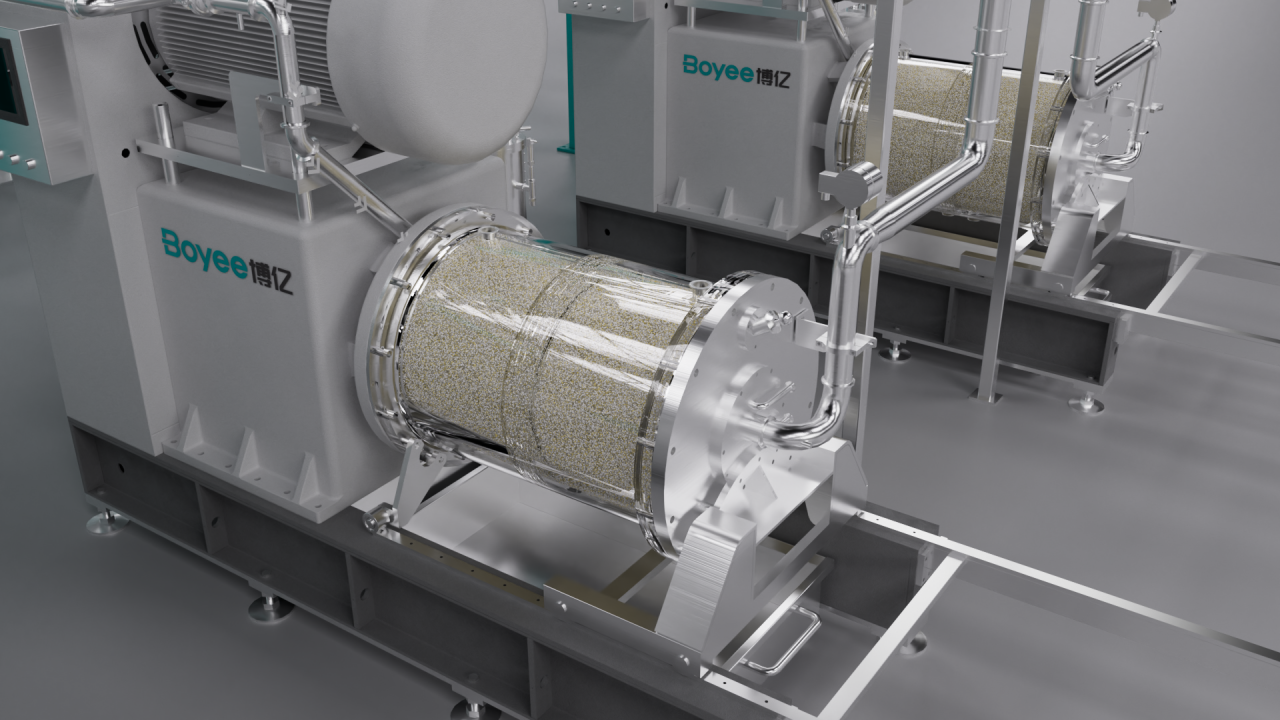

01. Grinding and dispersion process

Oxide solid electrolyte, the raw material is mechanically mixed and refined by wet grinding to improve the uniformity and activity of the material.

For example, in the preparation of the LATP oxide solid electrolyte in the form of NASICON, a solvent is added to the zirconia tank and the zirconia mill is used for grinding.

After grinding, the slurry is separated by sedimentation to remove impurities and obtain a wet oxide electrolyte, which is then dried to obtain the final oxide solid electrolyte.

This process pays attention to the purity and mixing uniformity of the raw material to ensure the stable performance of the electrolyte. Sulfide solid electrolyte, sulfide materials usually need to be ground in an inert gas environment to prevent it from reacting with oxygen or moisture in the air.

For example, in the preparation of the Li6PS5CL (LPSCL) sulfide solid electrolyte, lithium sulfide, phosphorus pentasulfide and lithium chloride are mixed in a certain proportion and then mechanically ground. During the grinding process, the chemical bonds of the raw materials are broken, and the mixing at the atomic level is achieved, resulting in a sulfide solid electrolyte precursor with high ionic conductivity.

This process emphasizes the protection of raw materials and efficient mixing to improve the performance of electrolytes.

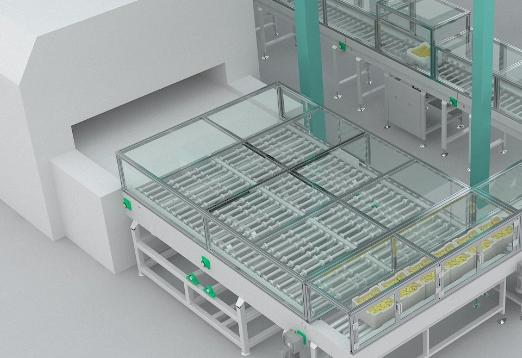

02. Sintering process

The sintering process of oxide solid electrolytes is relatively simple and is usually carried out at high temperatures.

For example, in the preparation of LLZO-type oxide solid electrolytes, conventional sintering methods are used to hold the mixture at high temperatures for several hours to form a dense solid structure.

In recent years, additional radiating sintering methods such as discharge plasma sintering (SPS) have also been applied to the preparation of oxide solid electrolytwhich can achieve densification in a short time at low temperature and effectively reduce energy consumption.

The sintering process of sulfide solid electrolyte is relatively complicated, because its material is volatile and decomposition at high temperature, and it is easy to react with oxygen in the air.

Therefore, the sintering of sulfide solid electrolytes is usually carried out under inert gas protection, and the temperature control is more strict.

For example, in the preparation of LGPS sulfide solid electrolytes, the low-temperature sintering process after high-energy grinding is used to obtain high-performance sulfide solid electrolytes by precisely controlling the sintering temperature and time.

In addition, in order to inhibit the volatilization of lithium elements, researchers have also developed new sintering technologies such as "reactive flash firing" to further optimize the performance of sulfide solid electrolytes. With the continuous development of new energy technologies, the preparation process of these two solid-state electrolytes will also continue to be optimized and innovative to meet the higher requirements of future battery technology.