一. Issues related to solid-phase synthesis

1.The problem of ball mill wall adhesion caused by sulfide characteristics and its solutions

Problem: During the solid-phase synthesis of sulfides, the phenomenon of wall adhesion is prone to occur during the ball milling process.

Solution: The problem of wall adhesion can be solved by adding a dispersant.

2. Temperature rise issues and solutions for ball mills or high-speed stirring equipment

Problem: During the ball milling or high-speed stirring process, the equipment is prone to temperature rise and needs to operate intermittently.

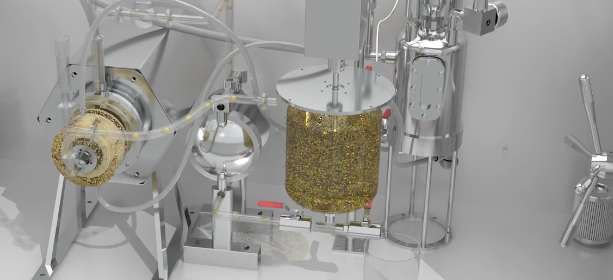

Solution: By using the built-in cooling system of the Boyee bead mill, the heat generated during the grinding and dispersion processes can be addressed, achieving continuous cooling.

The picture shows the grinding section in the Boyee sulfide solid electrolyte production line solution

3. High-temperature sintering equipment and temperature control issues

Question:High-temperature sintering (such as sulfide solid-phase synthesis in the laboratory usually requires 500℃) or quenching and other methods have high requirements for equipment temperature control and tolerance. What methods or equipment are commonly used in industry?

Answer: High-temperature sintering can be carried out using a dedicated sintering furnace, and its temperature control and tolerance must meet the production requirements.

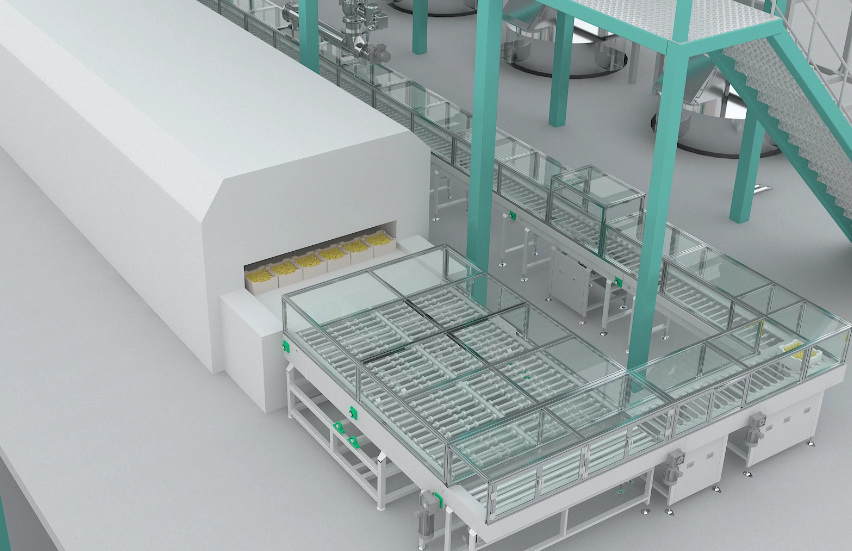

The picture shows the sintering section of the Boyee oxide solid electrolyte production line solution

4. How to avoid a decrease in conductivity after large-scale preparation

Question: After large-scale preparation, due to the presence of impurity phases, the conductivity of the electrolyte will inevitably decrease. How can this be avoided in industry?

Solution: By optimizing the formula and technical processes, the generation of impurity phases can be reduced, thereby enhancing the conductivity of the electrolyte.

二. Issues related to liquid-phase synthesis

1. Solvent screening principles

What are the solvent screening principles used in liquid-phase synthesis? How to balance costs, avoid side reactions, solvent toxicity, flammability and explosiveness and other factors?

Solution: Solvent screening needs to comprehensively consider factors such as cost, side reactions, toxicity, flammability and explosiveness.

2. Solvent post-treatment methods

Question: What are the post-treatment methods for solvents in liquid-phase synthesis? What are the commonly used methods in industry?

Solution: The post-treatment of solvents adopts the method of recycling and reuse to reduce waste and environmental pollution.

The picture shows a schematic diagram of the Boyee sulfide solid electrolyte production line solution

3. The issue of low solubility when doping metal sulfides

Question: When doping metal sulfides, there is a problem of low solubility. How should this be considered in industry?

Solution: The issue of low solubility during the doping of metal sulfides can be addressed by optimizing the formula. The specific solution should be determined based on product requirements and process conditions.

4. Carbonization of residual solvents and Solutions

Question: Residual solvents may carbonize during subsequent sintering, affecting the performance of the entire battery. How can this be avoided in industry?

Solution: Low-boiling-point solvents can be selected to reduce the carbonization phenomenon of residual solvents during the sintering process.

三. Other related issues

Post-treatment methods for the prepared hydrogen sulfide

Question: How should the hydrogen sulfide produced during the preparation process be post-treated?

Answer: Hydrogen sulfide can be post-treated through specialized tail gas treatment equipment, such as by means of absorption and conversion to transform it into harmless or low-toxic substances. The specific treatment should be determined based on environmental protection requirements and process conditions.